close

Choose Your Site

Global

Social Media

Views: 0 Author: Harris LIU Publish Time: 2025-10-25 Origin: Harris LIU

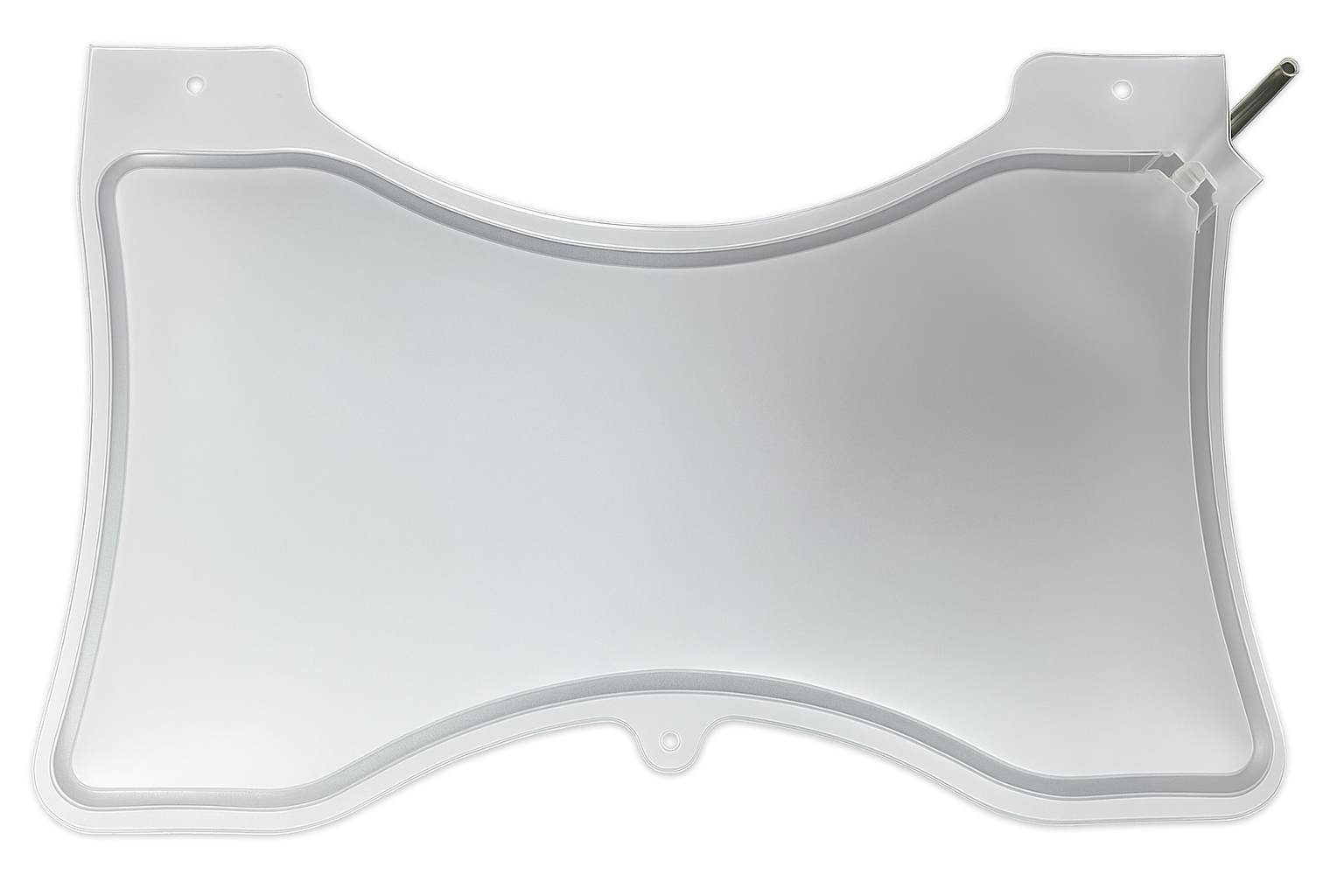

As the automotive industry continues to raise standards for safety and comfort, the market demand for seat and backrest air bladders is rapidly increasing.

To help manufacturers achieve high-quality and high-efficiency production, HETRO Automation has launched a new generation of automotive air bladder production equipment.

By combining advanced high-frequency welding technology with intelligent automation control systems, we provide customers with reliable, stable, and efficient production solutions.

HETRO's air bladder production equipment is specially designed for air bladder products with a single-end tailpipe.

The entire production line features a compact structure and a high level of automation, covering the complete process from tailpipe welding to air bladder body forming.

Modular Design – For different tailpipe specifications, quick-change feeding modules can be configured to achieve flexible production.

Directional Consistency Control – For long and curved tailpipes with specific directional requirements, the system ensures consistent bending direction and product uniformity.

Multi-Angle Compatibility – Capable of producing air bladders where the tailpipe and air bladder body are set at various angles, meeting diverse product design needs.

Parallel Welding Process – Tailpipe and air bladder body welding occur at separate stations simultaneously, significantly increasing production speed and improving weld quality.

Optional Automatic Punching Function – For products requiring holes, an automatic positioning punching process can be integrated into subsequent steps for full-line automation.

air bladder products operate in high-temperature, high-pressure environments and demand exceptional welding strength and durability.

Traditional thermal bonding methods often fail to meet these stringent requirements.

HETRO Automation adopts high-frequency welding technology, achieving strong, flawless, and uniform welds in less time.

Strong and airtight weld seams

Smooth and aesthetically pleasing surface finish

Long-term durability meeting automotive industry standards

With high-frequency welding, air bladders produced by HETRO equipment feature superior appearance, excellent strength, and outstanding reliability — the ideal choice for automotive seat air bladder manufacturing.

The entire production system is equipped with a fully automated control platform, enabling seamless integration of feeding, positioning, welding, punching, and inspection processes.

This ensures stable production, consistent cycle times, and significantly enhanced productivity.

Additionally, the equipment features an optimized structure for easy operation and simplified maintenance, reducing downtime and labor requirements — delivering high efficiency with lower operational costs.

HETRO Automation upholds the philosophy of “Quality First, Innovation Driven”, committed to providing world-class manufacturing solutions for automotive air bladder production.

Through the integration of high-frequency welding and intelligent automation, we empower our customers to achieve higher productivity, superior quality, and stronger competitiveness in the global market.

HETRO Automation — Making High-Quality Manufacturing Smarter.