close

Choose Your Site

Global

Social Media

Views: 0 Author: Harris LIU Publish Time: 2026-01-21 Origin: Site

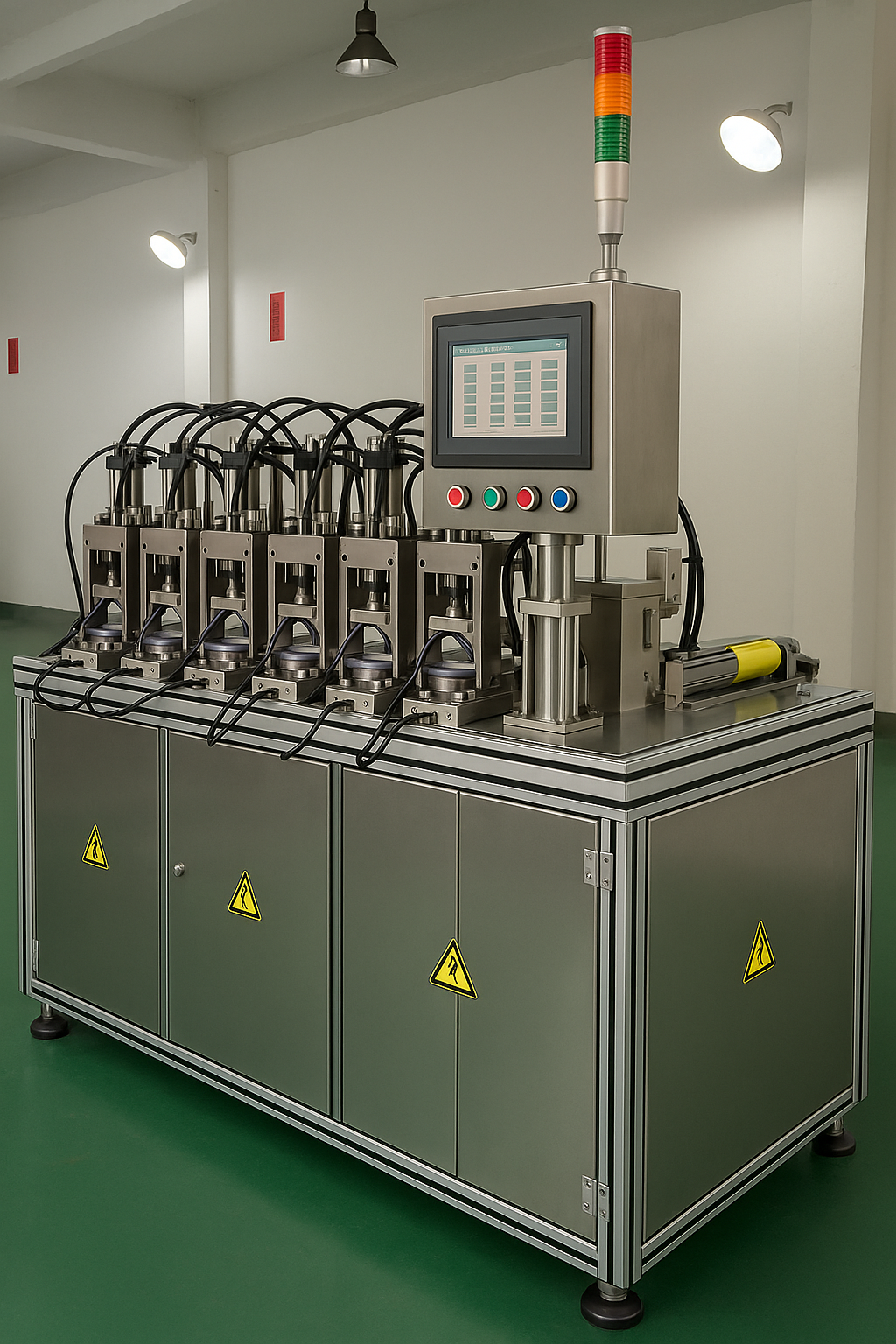

In the field of medical consumables and bag product manufacturing, efficiency, stability, and cost control have always been the core concerns of enterprises. Based on this, we have launched a fully upgraded high-automation bag product production line on the basis of the standard automated production line, with a higher level of automation and stronger process compatibility, to help customers achieve efficient and stable large-scale production.

I. Comprehensive Upgraded Automation Capability

The production line can automate several key processes for bag products, including:

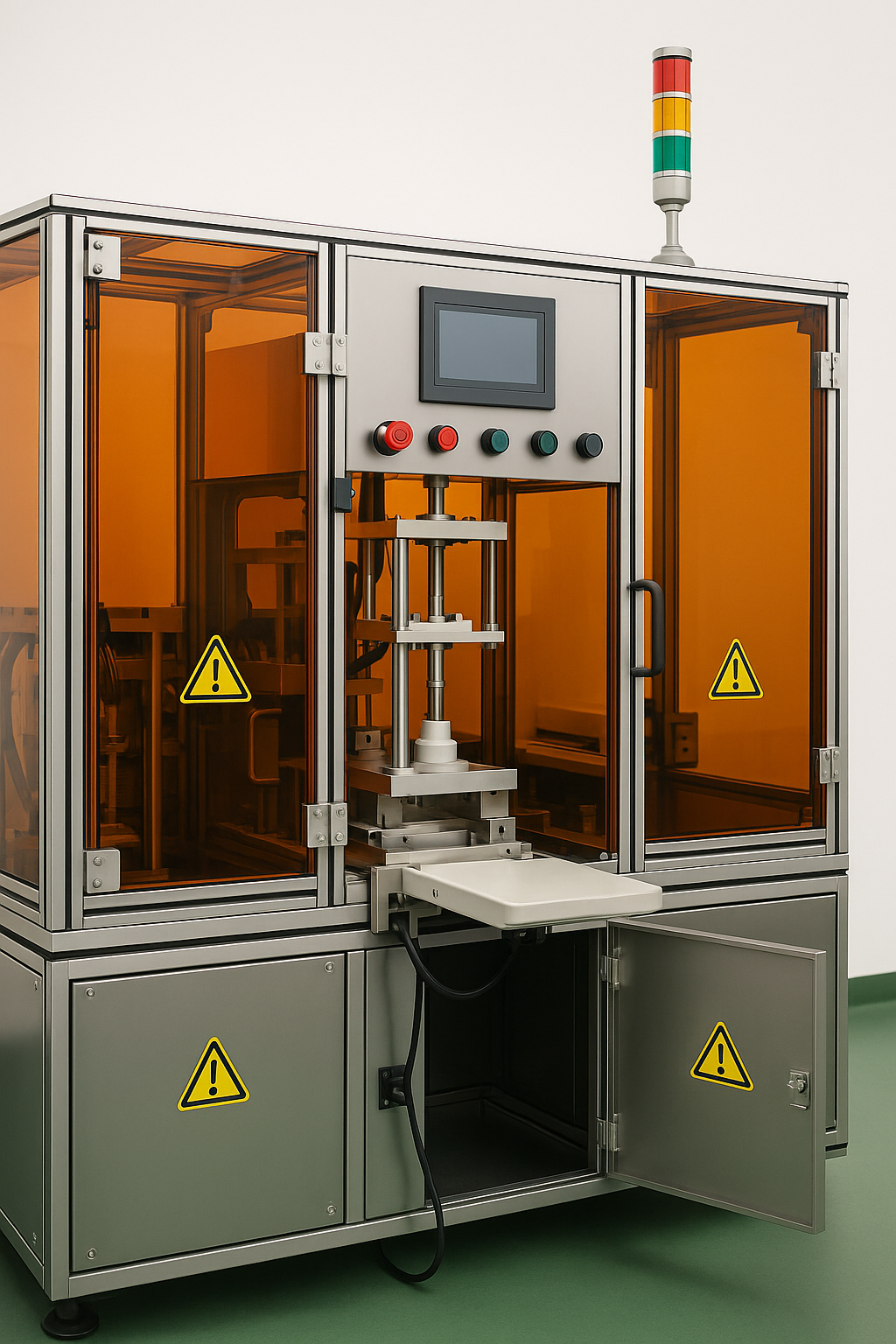

II. Advanced Detection to Ensure Assembly of Qualified Products

The production line can integrate an automatic leak detection function and move the detection process to before the valve assembly. By completing the bag leak detection before assembly, it ensures that all products entering the subsequent assembly processes are qualified, avoiding the following issues at the source:

III. Automatic Edge-Tearing Solution for Diverse Product Structures

For bag products that cannot be formed by cutting tools, an automatic edge-tearing device can be installed on this production line. After the edge-tearing process, the products will be automatically aligned neatly, facilitating the connection with subsequent processes or centralized material collection, further enhancing the degree of automation and site tidiness.

IV. Cost Reduction and Efficiency Improvement, Simplifying Production Management

As a highly automated intelligent production line, this equipment can significantly reduce human involvement: