close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-11-10 Origin: Site

The medical device manufacturing industry is continuously evolving, and urine bag production lines are no exception. While the core function of these machines remains the same—to produce safe and reliable urine bags—significant innovations have emerged to enhance their performance, flexibility, and efficiency. For manufacturers looking to stay competitive, understanding these advancements is crucial. Below, we explore the key innovations shaping the next generation of Urine Bag Machines production lines.

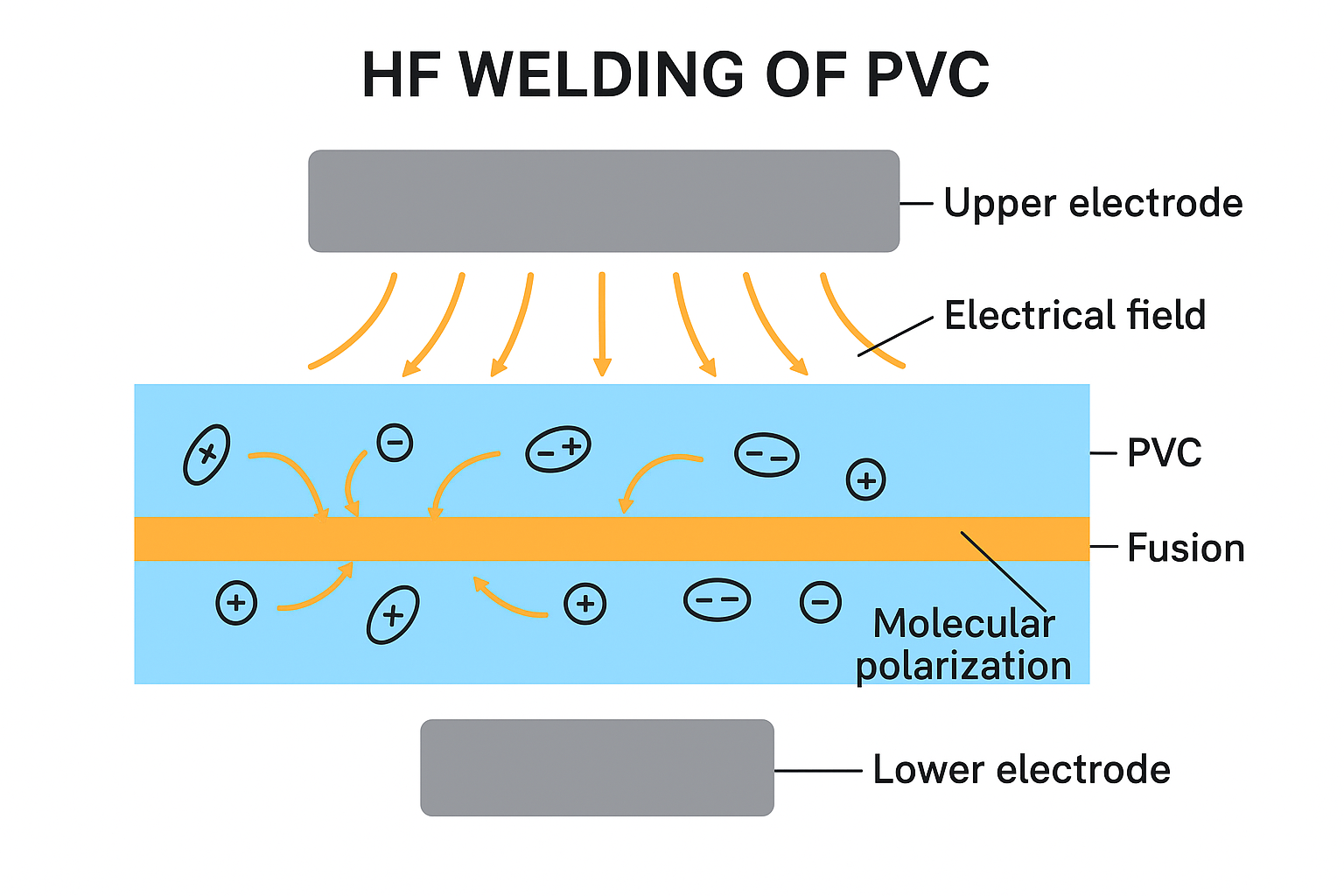

At the heart of urine bag production lies high-frequency (HF) welding, and recent innovations have made this process more precise and energy-efficient. Modern Urine Bag Machines feature improved HF generators that offer better temperature control and reduced power consumption. Additionally, advanced electrode designs ensure uniform heat distribution, resulting in stronger, more consistent seals. These innovations not only enhance product quality but also reduce material waste and operational costs.

One of the most impactful innovations in Urine Bag Machines is the shift toward modular design. Unlike traditional monolithic production lines, modular systems allow manufacturers to start with a basic setup and integrate additional functionalities as needed. For example, production lines can now be equipped with optional modules for specialized tasks like valve assembly, tube welding, or leak testing. This scalability ensures that manufacturers can adapt to changing market demands without investing in entirely new equipment.

Modern Urine Bag Machines are increasingly equipped with sensors and IoT-enabled devices to monitor production parameters in real time. These systems track critical metrics such as welding temperature, cycle time, and material feed accuracy. By collecting and analyzing this data, manufacturers can identify inefficiencies, predict maintenance needs, and optimize production workflows. This focus on data-driven insights represents a significant step toward smarter, more responsive manufacturing.

Innovation isn’t limited to hardware—software advancements have also played a key role. Newer Urine Bag Machines feature intuitive human-machine interfaces (HMIs) with touchscreen controls and simplified programming options. These interfaces allow operators to monitor production status, adjust settings, and troubleshoot issues with minimal training. This reduces dependency on highly specialized technicians and streamlines day-to-day operations.

As sustainability becomes a priority across industries, Urine Bag Machines have also seen innovations aimed at reducing their environmental footprint. Energy-efficient motors, optimized heating systems, and reduced air consumption are some of the features that make modern production lines more eco-friendly. Additionally, the precision of advanced HF welding technology minimizes material waste, contributing to greener manufacturing processes.

Market demands for customized urine bags—such as those with unique sizes, shapes, or features—have driven innovations in machine flexibility. Modern Urine Bag Machines can quickly switch between different product specifications through programmable settings and interchangeable molds. This agility allows manufacturers to cater to diverse customer needs without significant downtime or retooling costs.

The latest innovations in Urine Bag Machines production lines are paving the way for more efficient, adaptable, and intelligent manufacturing. From advanced high-frequency welding and modular designs to real-time data monitoring and user-friendly interfaces, these advancements are helping manufacturers meet the growing demands of the medical device market.

At Suzhou HETRO Automation Equipment Co., Ltd., we are committed to integrating these innovations into our urine bag production solutions. Our focus on high-frequency technology and modular systems ensures that our clients stay at the forefront of the industry.