close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-11-05 Origin: Site

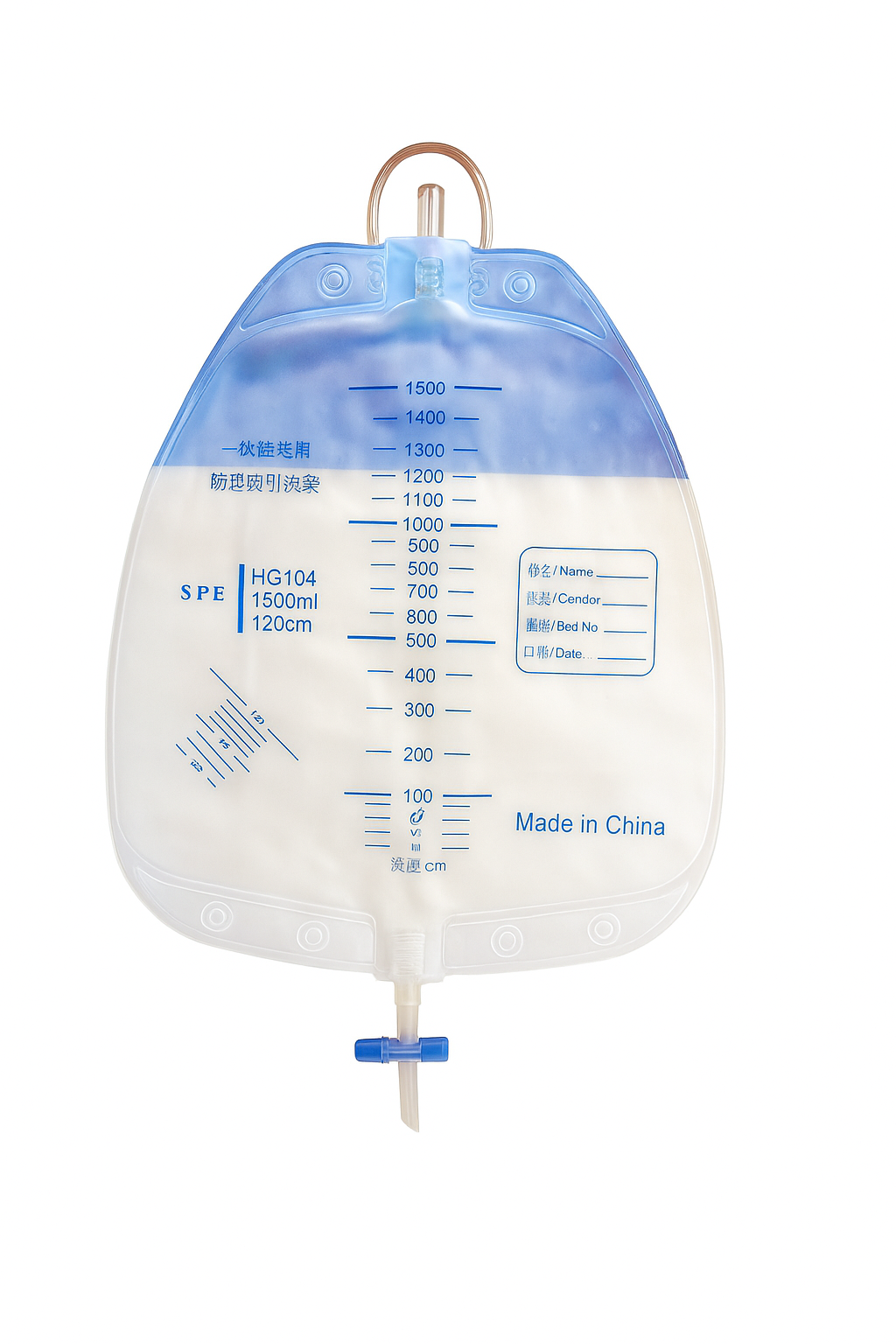

Regular and proper maintenance is not just about fixing problems; it's a crucial practice to prevent them. For urine bag machines built on high-frequency technology and modular designs, a disciplined maintenance routine ensures consistent product quality, minimizes unplanned downtime, and extends the equipment's operational life. This guide outlines the essential practices for keeping your production line running smoothly.

Consistency is key. Establishing simple, repeatable checks can catch small issues before they escalate.

Cleanliness: Keep the machine, especially the high-frequency welding area, free from plastic debris and dust. Use a soft brush or cloth. Avoid harsh chemicals that could damage electrical components.

Visual Inspection: Before starting, look for any obvious signs of wear, loose parts, or damage to cables and hoses.

Air Pressure: Check that the air compressor and filters are functioning, and that the air pressure is stable and meets the machine's requirement. Fluctuations can affect welding consistency.

Lubrication: Follow the manufacturer's manual to lubricate moving parts like guide rails and bearings at recommended intervals.

The HF system is the heart of your machine, and its maintenance demands particular attention.

Electrode (Mold) Cleaning: Residue can build up on the welding electrodes over time, leading to weak or inconsistent seals. Regularly clean the electrode surfaces with a recommended solvent or fine abrasive pad to ensure optimal heat transfer.

Tightness Check: Periodically ensure that the electrodes and their mounting plates are securely fastened. Loose connections can cause arcing and damage the molds.

Generator Vigilance: Pay attention to any unusual sounds from the HF generator and ensure its ventilation ports are not blocked. Overheating is a primary cause of generator failure.

One of the greatest advantages of a modular machine is how it simplifies upkeep.

Isolate and Address: If a problem arises in a specific module (e.g., the feeding system), your operators can often focus troubleshooting on that unit without disrupting the entire line. This makes diagnostics faster and less intimidating.

Scheduled Module Checks: Plan maintenance schedules for individual modules based on their usage. For instance, the sealing module might need more frequent attention than the stacking module.

Simplify Parts Management: Keeping critical spare parts for key modules (like a spare PLC or servo driver) can drastically reduce repair wait times.

Beyond daily care, a proactive long-term strategy is essential.

Scheduled Professional Service: While daily maintenance can be handled by your team, partner with your supplier for an annual or bi-annual professional inspection. They can calibrate the system, check internal components, and identify potential issues that are not visible to the naked eye.

Keep a Log: Maintain a detailed maintenance logbook. Record all services, parts replacements, and any irregularities. This history is invaluable for troubleshooting recurring problems and understanding the machine's lifecycle.

A well-maintained urine bag machine is a reliable and productive asset. By focusing on the core high-frequency system and utilizing the inherent advantages of a modular design, you can build a maintenance routine that is both effective and manageable.

At Suzhou HETRO Automation, our Standard Urine Bag Drainage Bag Automatic Production Line is designed with serviceability in mind. We stand behind our equipment with a 12-month quality guarantee and are committed to providing the technical support and maintenance guidance you need to keep your production on track.